MBR stands for Membrane Bio-Reactor (membrane biofilter), which can be broadly defined as the microbial treatment system of wastewater by membrane filtration.

- They are highly effective in reducing both organic and inorganic components as well as microorganisms in waste water.

MBR can be applied with anaerobic or aerobic filter.

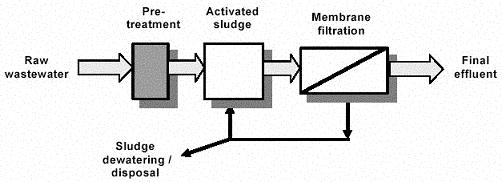

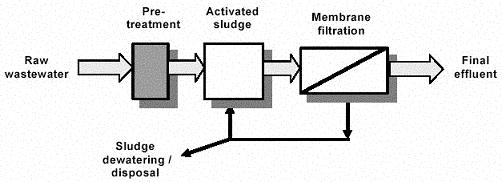

Application of MBR - a combination of membrane filtration and biofilter as a step in wastewater treatment can replace (in some cases) the role of separating sediment of secondary sedimentation tanks and Inlet filter can be used to remove secondary sedimentation tanks and operate at higher MLSS concentrations.

Diagram of technological lines with MBR:

-

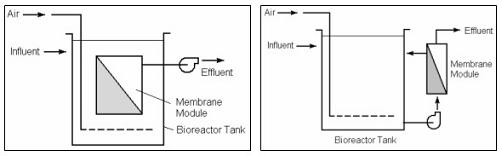

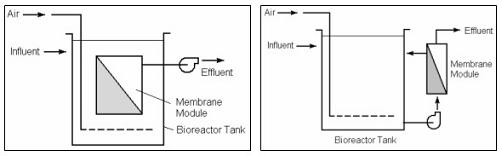

Diagram of Flood Type and Outside Type of MBR Membrane Modulus:

-

MBR-1000 membrane's specifications:

Material: Polypropylene

Material: Polypropylene

Capillary thickness: 40 ~ 50 μm

Capillary capillary diameter: 450 μm

Capillary cavity diameter: 0.01 ~ 0.2 μm

Air permeability: 7.0 x 10-2 cm3/cm2 • S • cmHg

Foam: 40 ~ 50%

Tensile strength: 120,000 kPa

Design filtering intensity: 6 ~ 9 L/m2/h

Modular area: 8 m2 / module

Operating Pressure: -10 ~ -30 kPa

Capacity: 1.0 ~ 1.2 m3/day

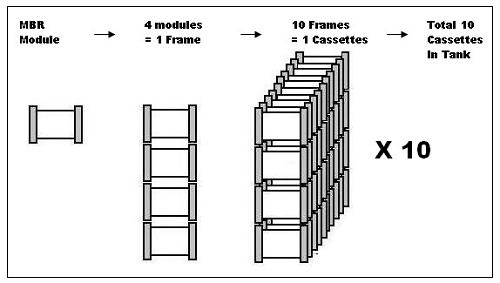

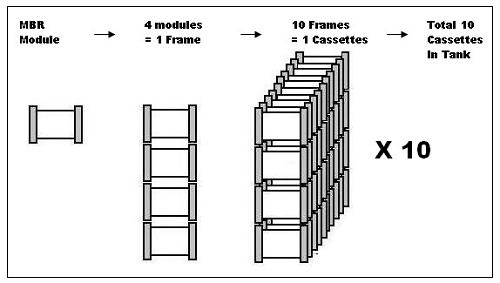

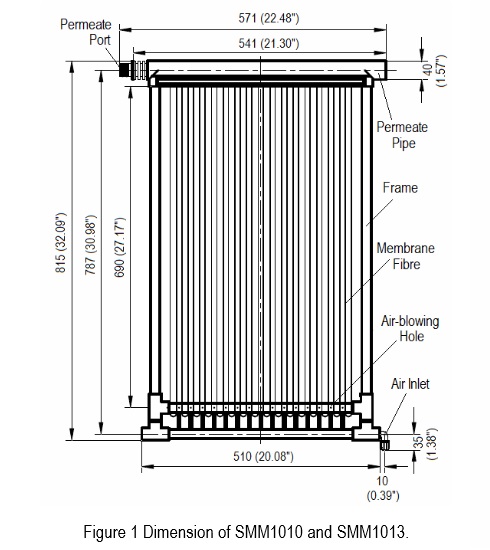

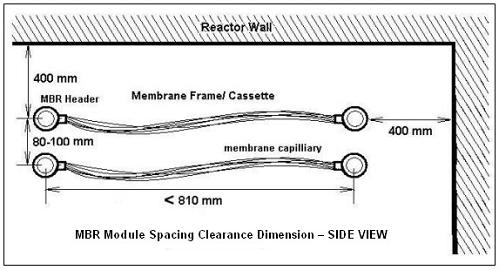

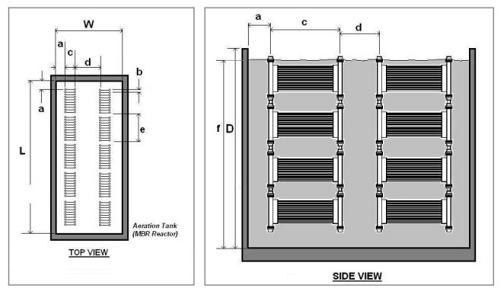

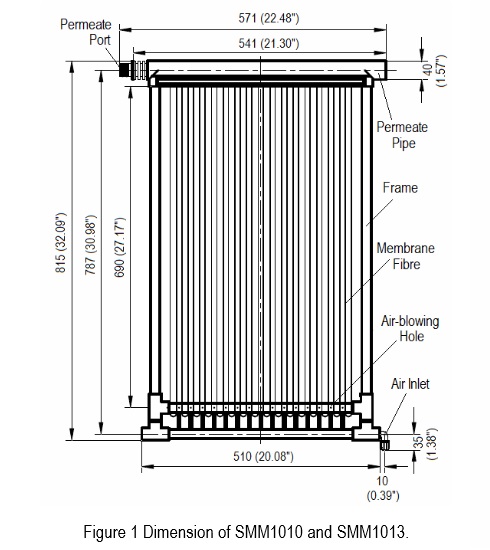

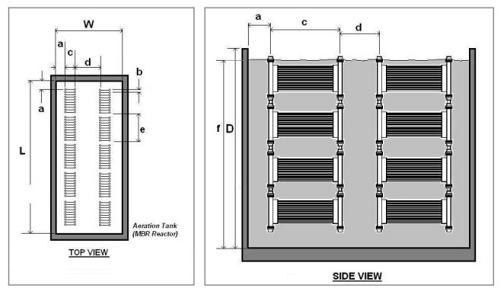

Filter size and method of MBR membrane module assembly:

That is, every 4 modules are assembled into a block, 10 blocks into 1 block, 10 blocks in a filter tank.

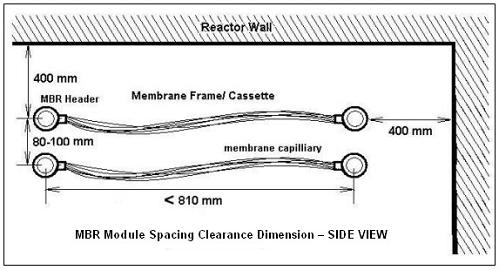

MBR module and blocks size:

![]()

Filter size: W = 4000 mm; L = 7000 mm; D = 3500 mm; f = 3000 mm

MBR module size: a = 400 mm; b = 100 mm; c = 800 mm; d = 1100 mm

MBR membrane is designed in a modular assembly module which is easy to maintain and upgrade later.

Share:

Material: Polypropylene

Material: Polypropylene